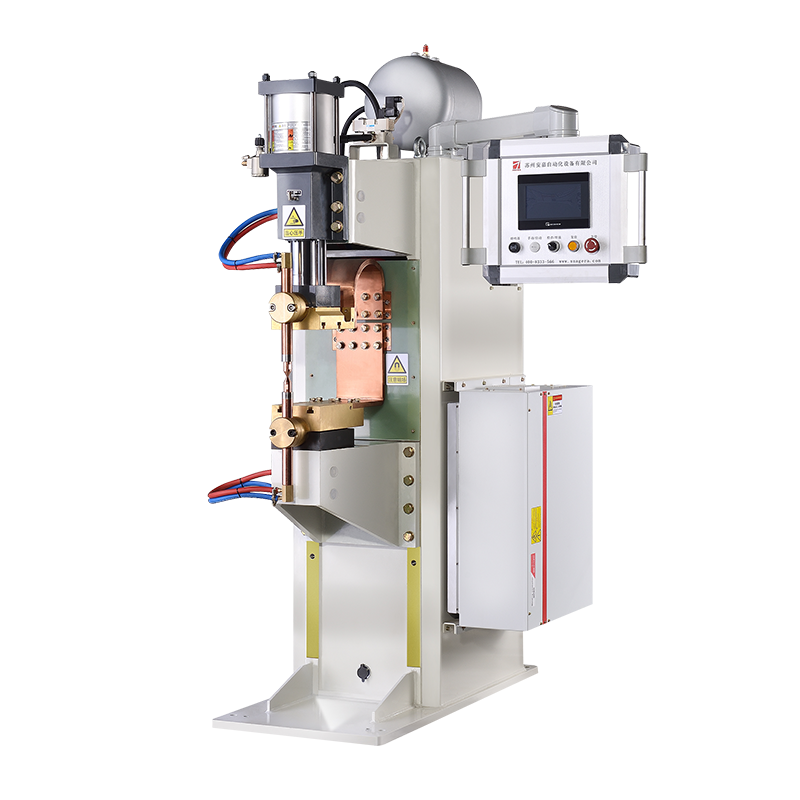

ADB-460 Platform mashiinka alxanka kaalinta

Hordhac Product

Hordhac Product

-

si wax ku ool ah u xakameyso spatter alxanka

Heerkulka kulaylka ee joogtada ah ee ay dhaliso soosaarka siman ee hadda jira ee alxanka dhibcaha IF ayaa ka dhigaya heerkulka nugget si joogto ah u kaca.Isla mar ahaantaana, xakamaynta saxda ah ee jiirada kor u kacaysa ee hadda iyo wakhtigu ma keeni doonto qulqulo sababtoo ah kulaylka boodboodka iyo wakhtiga kor u kaca ee aan la xakamayn karin.

-

Waqti gaaban oo awood ah, hufnaanta kulaylka sare

Alxanka booska IF wuxuu leeyahay alxanka wax soo saarka siman, kaas oo hubinaya waxtarka sare iyo joogtada ah ee kulaylka alxanka.Oo wakhtiga ku-korontadu waa gaaban yahay, oo gaadhay heerka ms, taas oo ka dhigaysa alxanka aagga kuleylku saameeyay mid yar, iyo kala-goysyada alxanka ayaa u samaysan si qurux badan.

-

Xaqiijinta xakamaynta sare

Sababo la xiriira soo noqnoqoshada sare ee shaqada (sida caadiga ah 1-4KHz) ee inta jeer ee dhexdhexaadka ah inverter booska alxanka, saxnaanta xakamaynta jawaab celinta waa 20-80 jeer ka mid ah AC guud mishiinka alxanka kaalinta iyo mishiinka sare hagaajinta mishiinka alxanka, iyo gacanta wax soo saarka u dhigma. saxnaanta sidoo kale waa mid aad u sareysa.

-

Badbaadinta tamarta 30%

Badbaadso tamarta, badbaadi tamarta alxanka meel kasta, oo gaabin wareegga alxanka, gaar ahaan ku habboon alxanka alxanka alxanka iyo biraha aadka u dhaqda.

-

Culayska dheelitirka qalabka

Waxaa loo isticmaalaa alxanka dhibicda iyo alxanka saadaasha lowska ee birta xoogga sare iyo birta sameeyay kulul ee warshadaha wax soo saarka baabuurta, alxanka bar iyo multi-dhibcood alxanka saxan bir-yar oo caadi ah, saxan bir ahama, saxan aluminium iyo silig, iska caabin ah. alxanka iyo bar alxanka silig naxaas in warshadaha korontada danab sare iyo hooseeyo, brazing saxan naxaas, alxanka dhibco lacag ah oo isku dhafan, iwm.

Tusaalooyinka alxanka

Tusaalooyinka alxanka

Saxan aluminium ah

Faransiiska hex nuts

Motor stator xiriir jilicsan

saxan tijaabada kursiga birta xoogga sare leh

feeraha xoojinta

lowska wareegsan

Hababka Haydarooliga ee qulqulka qulqulka

hagaajinta kursiga

saxan qalin ah

Bir daxal laheyn

silig terminal

Saxan dhexda dheer ee hore ee tuubada dunta leh

Faahfaahinta alxanka

Faahfaahinta alxanka

Halbeegyada alxanka

Halbeegyada alxanka

| Qaabka | ADB-5 | ADB-10 | ADB-75T | ADB100T | ADB-100 | ADB-130 | ADB-130Z | ADB-180 | ADB-260 | ADB-360 | ADB-460 | ADB-690 | ADB-920 | |

| Awoodda la qiimeeyay | KVA | 5 | 10 | 75 | 100 | 100 | 130 | 130 | 180 | 260 | 360 | 460 | 690 | 920 |

| Bixinta Korontada | ø/V/HZ | 1/220V/50Hz | 3/380V/50Hz | |||||||||||

| Cable Primary | mm2 | 2×10 | 2×10 | 3×16 | 3×16 | 3×16 | 3×16 | 3×16 | 3×25 | 3×25 | 3×35 | 3×50 | 3×75 | 3×90 |

| Ugu badnaan Primary Current | KA | 2 | 4 | 18 | 28 | 28 | 37 | 37 | 48 | 60 | 70 | 80 | 100 | 120 |

| Wareegtada Waajibka lagu qiimeeyay | % | 5 | 5 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Cabbirka dhululubada alxanka | Ø*L | Ø25*30 | Ø32*30 | Ø50*40 | Ø80*50 | Ø100*60 | Ø125*100 | Ø160*100 | Ø160*100 | Ø160*100 | Ø200*100 | Ø250*150 | Ø250*150*2 | Ø250*150*2 |

| Cadaadiska Shaqada ugu badan (0.5MP) | N | 240 | 400 | 980 | 2500 | 3900 | 6000 | 10000 | 10000 | 10000 | 15000 | 24000 | 47000 | 47000 |

| Isticmaalka Hawada Culayska | Mpa | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 |

|

Isticmaalka Biyaha ee qaboojinta | L/Min | - | - | 6 | 6 | 8 | 12 | 12 | 12 | 12 | 15 | 20 | 24 | 30 |

|

Isticmaalka Hawada Culayska | L/Min | 1.23 | 1.43 | 1.43 | 2.0 | 2.28 | 5.84 | 5.84 | 5.84 | 5.84 | 9.24 | 9.24 | 26 | 26 |

Habka gaarka ah

Habka gaarka ah

Welder FAQ

Welder FAQ

- S: Electrodes-ka mashiinka alxanka ee barta ma u baahan yihiin in la sii kululeeyo?

J: Korodhku uma baahna kuleyl ka hor, laakiin xaaladaha qaarkood, kuleyliyaha ka hor wuxuu wanaajin karaa natiijooyinka alxanka.

- S: Waa maxay qaylada la soo saari doonaa inta lagu guda jiro habka alxanka ee goobta alxanka?

J: Habka alxanka ee mishiinka alxanka ee goobta ayaa soo saari doona buuq, waxaana loo baahan yahay tallaabooyinka ilaalinta sida dhegaha.

- S: Dayactirka mashiinka alxanka goobta ma lagu fulin karaa adiga keligaa?

J: Qaar ka mid ah hawlaha dayactirka ayaa lagu samayn karaa adiga keligaa, laakiin hawlo badan oo kakan ayaa u baahan doona inuu qabto farsamoyaqaan xirfad leh.

- S: Xagee loo baahan yahay alxanka barta in lagu rakibo?

J: alxanka barta wuxuu u baahan yahay in lagu rakibo meel hawo fiican leh, meel qalalan oo lagu xidho khadka korontada.

- S: Muddo intee le'eg ayay qaadanaysaa in la dayactiro alxanka barta?

J: Waqtiga dayactirku wuxuu ku xiran yahay kakanaanta hawsha dayactirka iyo darnaanta cilladda qalabka, waxayna caadi ahaan qaadataa saacado ilaa maalmo.

- S: Sidee loogu baahan yahay alxankaha meelaha lagu nadiifiyo?

J: alxanka barafka waa in lagu nadiifiyaa hawo ama saabuun, waana in aan lagu nadiifin biyo ama dareere kale.

Email noogu soo dir

Email noogu soo dir