ADB-360 Platform spot tjheseletsa mochini

Kenyelletso ea Sehlahisoa

Kenyelletso ea Sehlahisoa

-

Hatella ka katleho spatter ea welding 'me u fihlele litlamorao tse tsitsitseng le tsa boleng bo holimo

phepelo ea mocheso e tsoelang pele e hlahisoang ke phallo e bataletseng ea mochini oa welding oa maqhubu a mahareng o etsa hore mocheso oa nugget o tsoele pele.Ka nako e ts'oanang, taolo e nepahetseng ea moepa oa hona joale o ntseng o phahama le nako e ke ke ea baka spatter ka lebaka la ho tlola mocheso le nako e sa laoleheng ea ho phahama hona joale.

-

Nako e khuts'oane ea ho cheselletsa matla, ts'ebetso e phahameng ea mocheso, le sebopeho se setle sa welding

HAEBA inverter spot welder e na le sesebelisoa sa tjheseletsa se bataletseng, se netefatsang katleho e phahameng le phepelo e tsoelang pele ea mocheso oa welding.'Me matla a nako e khutšoanyane, a fihla boemong ba ms, e leng se etsang hore sebaka sa welding se amehang ke mocheso se senyenyane,' me manonyeletso a solder a thehoa ka mokhoa o motle.

-

Ho nepahala ha taolo e phahameng

maqhubu a phahameng a ho sebetsa (hangata ke 1-4KHz) ea mochini o tjheseletsang letheba la maqhubu, ho nepahala ha taolo ea maikutlo ke makhetlo a 20-80 ho feta mochini o tjheseletsang letheba oa AC le mochini oa tjheseletsa oa sebaka sa bobeli, le ho nepahala ha taolo ea tlhahiso le eona. hodimo haholo.

-

Ho boloka matla

ho boloka matla.Ka lebaka la ts'ebetso e phahameng ea mocheso, sesebelisoa se senyenyane sa tjheseletsa le tahlehelo e nyane ea tšepe, mochini oa tjheseletsa oa inverter o ka boloka matla a fetang 30% ho feta mochini oa tjheseletsa oa letheba la AC le mochini oa tjheseletsa oa sebaka sa bobeli ha o tjheseletsa sesebelisoa se tšoanang.

-

Mochini oa welding oa inverter o loketse ho leka-lekana ha motlakase oa grid, ntle le lisebelisoa tsa matšeliso a matla

E sebelisoa bakeng sa tjheseletsa ea matheba le tšupiso ea linate tsa tšepe e matla a phahameng le tšepe e chesang e entsoeng indastering ea tlhahiso ea likoloi, ho tjheseletsa sebakeng le lintlha tse ngata tsa tjheseletsa tsa poleiti ea tšepe e tlase ea khabone, poleiti ea tšepe e sa hloekang, poleiti e entsoeng ka galvanized, poleiti ea aluminium le terata, ho tiisa brazing le ho tjheseletsa terata ea koporo indastering ea motlakase e phahameng le e tlase, welding ea sebaka sa silevera, brazing ea lijana tsa koporo, welding e kopantsoeng ea silevera, jj.

Mehlala ea Welding

Mehlala ea Welding

Letlapa la aluminium

letlapa la koporo la kamore ea mouoane

French hex nut

matla a phahameng tšepe setulo teko poleiti

ho matlafatsa kgopo

nate e chitja

motho ea lokisang setulo

ho kopana le silevera

poleiti e entsoeng ka silevera

ts'epe e sa beng le mabali

terata ea ho qetela

thermoformed tšepe square nut

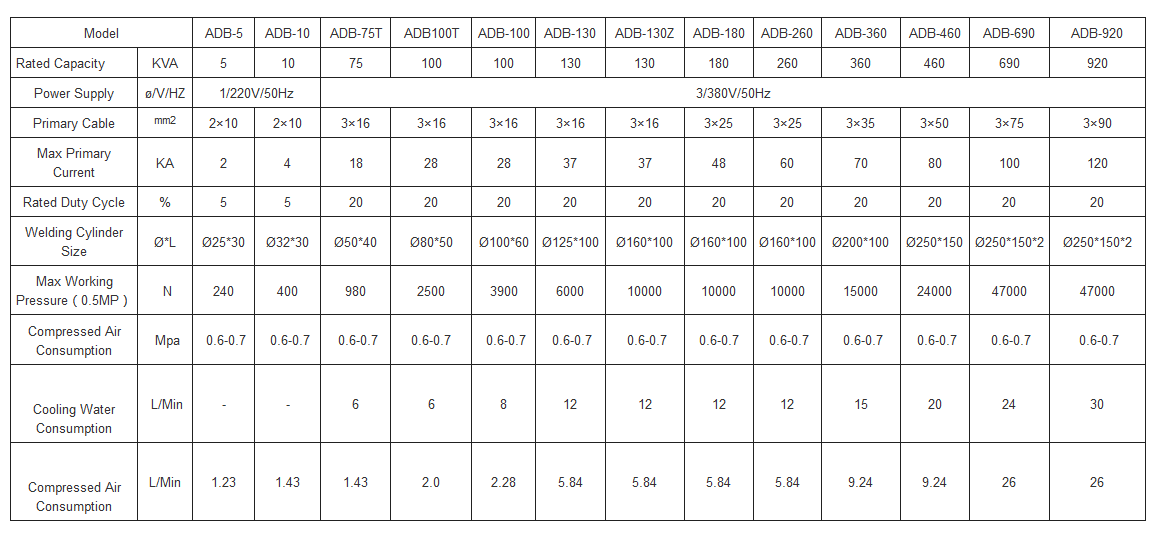

Lintlha tsa Welder

Lintlha tsa Welder

Mokhoa o Tloaelehileng

Mokhoa o Tloaelehileng

Welder FAQ

Welder FAQ

- P: Tlhokomelo ea li-spowelder e etsahala hangata hakae?

K: Khafetsa ea tlhokomelo e lokela ho khethoa ho latela tšebeliso ea mochini oa ho cheselletsa sebaka le tikoloho ea tlhahiso, 'me hangata ho khothaletsoa ho lokisa hang ka khoeli.

- Q: Joang ho khetha e loketseng phepelo ea matla bakeng sa letheba tjheseletsa mochini?

A: Khetho ea phepelo ea motlakase ea mochini oa welding oa letheba e lokela ho khethoa ho latela matla a lisebelisoa le tikoloho ea ts'ebeliso ho netefatsa hore lisebelisoa li ka sebetsa ka mokhoa o tloaelehileng.

- P: Ke mehato ea mofuta ofe ea ts'ireletso eo li-welders tsa mabala li hlokang ho li sebelisa?

K: Li-welders tsa Spot li hloka tšebeliso ea likhalase tse sireletsang, liatlana, le lisebelisoa tse ling tsa tšireletso ho boloka basebetsi ba sireletsehile.

- P: Phepelo ea motlakase ea mochini oa tjheseletsa ea letheba e lokela ho hokahanngoa joang?

A: Motlakase o lokela ho hokeloa ho latela litlhoko tsa motlakase le litekanyetso tsa polokeho ea lisebelisoa.

- P: Bophelo ba ts'ebeletso ea welder ea sebaka bo bolelele bo bokae?

A: Bophelo ba tšebeletso ea mochine oa tjheseletsa letheba bo itšetlehile ka lintlha tse kang boleng ba thepa, tlhokomelo le tikoloho ea tšebeliso, hangata pakeng tsa lilemo tse 5-10.

- Q: Lebelo la tjheseletsa la welder ke eng?

A: Lebelo la welding le itšetlehile ka boholo le ho rarahana ha morero oa ho cheselletsa 'me hangata ke makhetlo a' maloa motsotsoana.

Re romelle lengolo-tsoibila

Re romelle lengolo-tsoibila